Cable Tray

Cable Tray is a facility necessary to install the cable, which provides eletricity, safely, acoiding any inter ference of other structures and provide electricity.

- Ladder Plate Type

- Channel Type

- Ladder Flat Bar Type

- Tray Load Test

- Onshore Cable Tray (Non-Welding Cable Tray System)

- Certification

- Patent

Ladder Plate Type

Ladder Plate Type Specification

| Height | 100, 150 |

| Width | 150, 300, 450, 600, 750, 900 |

| Thickness | 1.5, 1.6, 2.0, 2.3 |

| length Straight | 600-3000 |

| Angle Fitting | 30°, 45°, 60°, 90° |

| Radius Fitting | 300, 450, 600, 900 |

| Material | Pre-Galvanized, Hot-dip Galvanized, Stainless Steel 316, Aluminum |

| Coating Type | Bare, Hot-dip Galvanized, Powder Coating Hot-dip Galvanized + Powder Coating Electronic Galvanized + Powder Coating |

Channel Type

Channel Type Specification

| Height | 40, 50, 75 |

| Width | 50, 75, 100, 150, 200 |

| Thickness | 1.5, 1.6, 2.0, 2.3 |

| length Straight | 600-3000 |

| Angle Fitting | 30°, 45°, 60°, 90° |

| Radius Fitting | 300, 450, 600, 900 |

| Material | Pre-Galvanized, Hot-dip Galvanized, Stainless Steel 316, Aluminum |

| Coating Type | Bare, Hot-dip Galvanized, Powder Coating Hot-dip Galvanized + Powder Coating Electronic Galvanized + Powder Coating |

Ladder Flat Bar Type

Ladder Flatbar Type Specification

| Height | 38, 50 |

| Width | 100, 200, 300, 400, 500, 600, 700, 800, 900 |

| Thickness | 4.5, 5.0, 6.0 |

| length Straight | 600-3000 |

| Angle Fitting | 30°, 45°, 60°, 90° |

| Radius Fitting | 300, 450, 600, 900 |

| Material | Pre-Galvanized, Hot-dip Galvanized, Stainless Steel 316, Aluminum |

| Coating Type | Bare, Hot-dip Galvanized, Powder Coating Hot-dip Galvanized + Powder Coating Electronic Galvanized + Powder Coating |

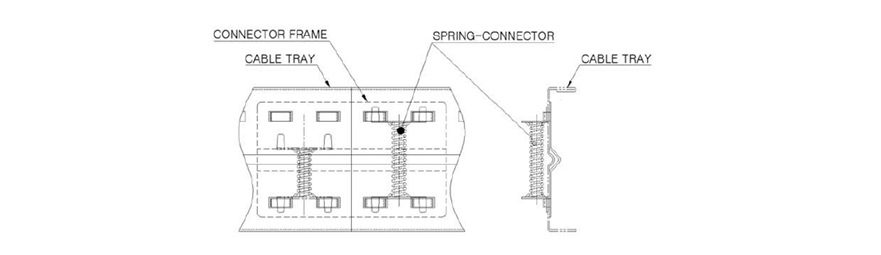

Onshore Cable Tray (Non-Welding Cable Tray System)

| Classification | Detail Information | ||

|---|---|---|---|

| Name of Product |

SPRING JOINT CONNECTOR | Development System |

Apply Non - Bolting System |

| Shape of Product |

|

||

| Functions | 좌우 2ea - 1set로 구성된 Spring 타입으로 하부 고정 후 스프링의 장력을 이용하여 상부홈에 고정하는 방식임 | ||

| Features of Product |

90% Reduction for Assemble Time | ||

Cable Tray Support

Suppory & T-bolt Fitting

Joint Bracket Fitting

Nuts & Washer Fitting

– Achievement of time-saving in assembly through improvement of a cable tray assembly method – Achievement of product light weighting – In case of a cable tray assembly, a technique of fitting system would be adopted

Cable Tray Joint